About Us

Good Spirits Bottling is a state-of-the-art bottling plant in Dundalk, Co. Louth, offering bespoke contract bottling solutions to spirits companies worldwide.

Our cutting-edge bottling machinery allows for tailored, adaptable alcohol bottling and labeling solutions to suit your unique requirements, whilst our high-tech blending plant is fully-equipped with regulatory-approved, precise and accurate control systems, as well as an on-site laboratory for product testing at each stage of development.

We are a passionate team with many years of beverage industry experience, dedicated to quality, safety and care of product.

Whether you require bespoke packaging, specialized labeling, or unique branding, GSB is dedicated to providing tailored solutions to make your vision a reality.

What we do

Blending

Our blending and chill filtration system have tank capacities of 50,000 litres. We have the most up to date equipment to offer expert blending for your quality liquid.

Bottling

Made for batch runs from 1000-100,000 bottles, our state-of-the-art bottling lines can accommodate various bottle sizes, shapes, and packaging requirements with ease.

Labelling

We offer wrap around label applications as well as ROPP closures and can accommodate novel or bespoke bottle shapes and labels. Hand-labelling is also possible.

Storage and Warehousing

Our alcohol warehouses are fully-bonded, state-of-the-art, purpose-built facilities, offering the best possible environment for cask storage.

Packing

Your products will be packed and ready for delivery as if they are our own. We work closely with you to ensure the finished pack is to the standard you are looking for.

Export Support

We have experience exporting to 25+ international markets and can assist you with logistics, supply chain management, and regulatory compliance.

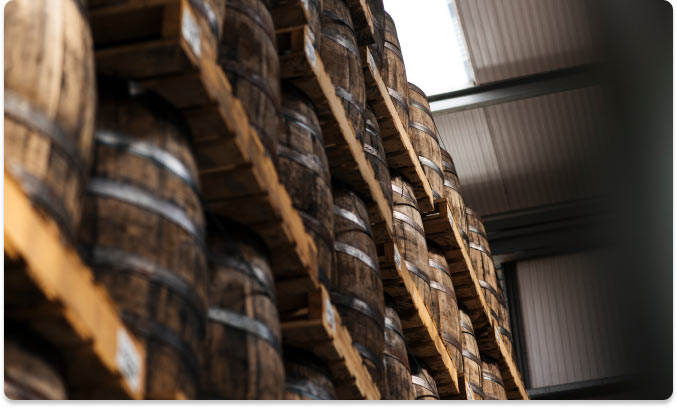

Cask Maturation

Cask maturation is a crucial stage that significantly influences the final flavor, aroma, and complexity of your spirit, and one that GSB take huge pride in perfecting for each of our clients.

Our expert team can assist you with spirit sourcing, cask sourcing, storage, monitoring, sampling, re-racking, bottling and custom labelling.

All stock is meticulously stored in GSB-controlled warehouses located in the Republic of Ireland. Our facilities boast state-of-the-art security measures, including surveillance systems, fire protection and ATEX ratings.

Your peace of mind is paramount to us, which is why OIST is insured by Allianz plc, with a dedicated policy, offering comprehensive coverage for our operations and assets.

Our on-site cooper Enguerrand, reviews the quality of casks inbounded and undertakes any repairs necessary. This ensures that the losses in spirit is kept to a minimum and there is longer durability of the wooden barrels which can then be refilled after bottling.

Irish Whiskey Bottling

Whatever your single-cask bottling requirements, GSB is here to accommodate. Our cutting-edge bottling machinery allows us to produce up to 1200 units of 750ml or 700ml whiskey bottles per hour, and can fulfil various bottle sizes, shapes, and packaging requirements with ease.

Our advanced bottling machinery and stringent quality control measures ensure that each bottle meets the highest standards of excellence. From filling to labeling, every step of the process is meticulously monitored to guarantee superior quality and consistency.

Need something out of the ordinary? At GSB, we pride ourself on our flexible, collaborative approach. We will work closely with our equipment support team to find innovative solutions for novel or bespoke corks, glass closures, and other packaging components.

Trust in our state-of-the-art bottling capacity to bring your products to market with efficiency, precision, and uncompromising quality. Experience the difference of working with a partner committed to excellence and innovation.

Additional Services

Industry-Leading Team

Kevin Donnelly

General Manager

Michael Cowman

Senior Business Development Manager

Anne Marie Kelly

Business Development Manager

Enguerrand Vandenbossche

Cooper/ Liquid Control

Yvonne Hughes

Cask Supply Chain Manager / Warehouse Manager

Michelle Boyle

Head of Finance

Neil McSorley

Production Manager

Ella Ghetler

Senior Supply Chain Manager

Donatas Jonkus

Engineering

Bronagh McKeown

Quality and Compliance Manager

Client Testimonials

Contact Us

For more general enquiries, please use the contact form on this page.

Our Location

Clermont Business Park, Haggardstown,

Co. Louth, A91 EHN4, Ireland

Information

Location

Clermont Business Park, Haggardstown,

Co. Louth, A91 EHN4, Ireland

© 2024 All Rights Reserved. Good Spirits Bottling Ltd | Privacy Policy | Terms of Purchase